Precision Measuring Instruments

Gauges

Precision gauges are manufactured in accordance with the requirements and specifications in accordance with ANSI reference standards. Precision gauges for quality assurance and repeated performance.

Use gauges made with the latest in CNC thread grinding machines.

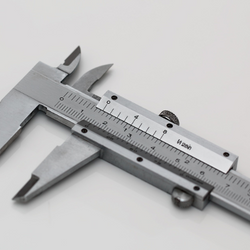

Calipers

Whether measuring internal dimensions, external dimensions, or depth the diverse range of caliper types caters to the specific needs of manufacturing processes, ensuring meticulous and reliable dimensional assessments.

Precision calipers are indispensable tools that offer accurate measurements. Choose between traditional vernier or modern digital versions.

Precision Measuring Instruments for Industrial Applications

Precision measuring instruments are tools used to obtain accurate measurements of physical dimensions, angles, alignment, and surface quality in industrial and manufacturing environments. These instruments help ensure parts meet design specifications, improve quality control, and reduce errors in machining, assembly, and inspection.

What Are Precision Measuring Instruments?

Precision measuring instruments include gauges, micrometers, calipers, dial indicators, height gauges, and other devices designed to measure linear dimensions, roundness, flatness, and alignment to tight tolerances. Unlike basic handheld tools, these instruments provide **high accuracy and repeatability** needed for quality assurance and inspection tasks.

Where Precision Instruments Are Used

Precision measuring tools are essential in operations such as:

- Machine shops and CNC manufacturing

- Quality control and inspection labs

- Production line verification and sampling

- Assembly and test fixtures

- Toolroom setup and calibration stations

Common Types of Instruments

- Calipers – Vernier, dial, and digital calipers for general measurements

- Micrometers – Outside, inside, and depth micrometers for fine dimensional accuracy

- Dial indicators – For runout, alignment, and deviation measurement

- Height gauges – For vertical dimension and layout checks

- Gauge blocks – Reference standards for calibration

- Protractors & angle gauges – For angular measurement

Why Precision Measuring Instruments Matter

Accurate measurement is critical for manufacturing quality and repeatability. Precision tools help:

- Verify part compliance to design tolerances

- Reduce scrap and rework from out-of-tolerance parts

- Ensure proper fit and function in assemblies

- Maintain consistency across production batches

How to Choose the Right Measuring Tool

- Match the tool’s accuracy and range to the measurement requirement

- Use digital readouts when high visibility and data collection matter

- Choose rugged construction for shop floor use

- Consider calibration traceability for quality systems

Common Measurement Mistakes and How to Avoid Them

- Using a tool outside its intended range — choose the correct size

- Reading incorrectly due to parallax — use digital indicators when possible

- Not calibrating tools regularly — establish a schedule

- Improper contact force — use consistent technique for repeatability

Benefits of Quality Precision Instruments

- Improved part quality and fewer defects

- Faster inspection cycles and better throughput

- Reliable measurements with reduced uncertainty

- Supports ISO and quality system compliance

- Long lifespan when properly maintained

Frequently Asked Questions

What’s the difference between calipers and micrometers?

Calipers measure a range of dimensions quickly and flexibly, while micrometers provide higher accuracy within a more limited range.

When should I use a dial indicator?

Use dial indicators for alignment, runout, and deviation checks where precision and repeatability are critical.

How often should measuring tools be calibrated?

Calibration frequency depends on usage and quality requirements — daily or weekly for shop tools in heavy use, and per quality plan for inspection lab instruments.

Related Categories

- Cutting Tools

- CNC Tooling & Accessories

- Measurement & Test Equipment

- Toolroom & Calibration Standards

-

__02768.1745334639.png?c=2)

Insize Dial Indicator, 25mm, graduation 0.1mm, Lug Back

MSRP: $125.97$111.35Supplied with limit pointers and bezel clamp. Optional accessory: backs, contact points.2318-25MSRP: $125.97$111.35 -

__22544.1745334539.png?c=2)

__22544.1745334539.png?c=2) MSRP: $51.88$45.86

MSRP: $51.88$45.86 -

__62740.1745334539.png?c=2) MSRP: $16.44$14.53

MSRP: $16.44$14.53 -

__96280.1745334539.png?c=2) MSRP: $46.33$40.96

MSRP: $46.33$40.96 -

__19160.1745334539.png?c=2) MSRP: $39.39$34.82

MSRP: $39.39$34.82 -

__30707.1745334637.png?c=2)

Insize 0-1" Dial Indicator with ISO17025 Calibration Cert

MSRP: $108.89$96.25Graduation .001". Comes w/ ISO17025 Calibration Cert with ship to address on cert. Meet ASME B89.1.10M-2001. Supplied with limit pointers and bezel clamp. Optional accessory: backs, contact points.2307-1CalMSRP: $108.89$96.25 -

__41995.1745334571.png?c=2)

Insize 0-12" Dial Caliper with ISO17025 Calibration Cert

MSRP: $230.58$203.83Comes w/ ISO17025 Calibration Cert with ship to address on cert. Shockproof dial indicatorMade of stainless steel.1311-12CalMSRP: $230.58$203.83 -

__12365.1745334507.png?c=2)

Insize 0-12" Digital Caliper with ISO17025 Calibration Cert

MSRP: $238.05$210.44Comes w/ ISO17025 Calibration Cert with ship to address on cert. Resolution: .0005"/0.01mm. Buttons: on/off, zero, inch/mm. Automatic power off, move the digital unit to turn on power. Battery CR2032. Data output. Made of stainless steel. Optional...1108-300CalMSRP: $238.05$210.44 -

__25675.1745334572.png?c=2)

Insize 0-6" Dial Caliper with ISO17025 Calibration Cert

MSRP: $144.11$127.40Comes w/ ISO17025 Calibration Cert with ship to address on cert. Shockproof dial indicatorMade of stainless steel.3/8" stem1311-6CalMSRP: $144.11$127.40 -

__42018.1745334507.png?c=2)

Insize 0-6" Digital Caliper with ISO17025 Calibration Cert

MSRP: $140.91$124.56Comes w/ ISO17025 Calibration Cert with ship to address on cert. Resolution: .0005"/0.01mm. Buttons: on/off, zero, inch/mm. Automatic power off, move the digital unit to turn on power. Battery CR2032. Data output. Made of stainless steel. Optional...1108-150CalMSRP: $140.91$124.56 -

__89946.1745334572.png?c=2)

Insize 0-8" Dial Caliper with ISO17025 Calibration Cert

MSRP: $169.73$150.04Comes w/ ISO17025 Calibration Cert with ship to address on cert. Shockproof dial indicatorMade of stainless steel.1311-8CalMSRP: $169.73$150.04 -

__00802.1745334507.png?c=2)

Insize 0-8" Digital Caliper with ISO17025 Calibration Cert

MSRP: $168.67$149.10Comes w/ ISO17025 Calibration Cert with ship to address on cert. Resolution: .0005"/0.01mm. Buttons: on/off, zero, inch/mm. Automatic power off, move the digital unit to turn on power. Battery CR2032. Data output. Made of stainless steel. Optional...1108-200CalMSRP: $168.67$149.10