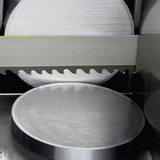

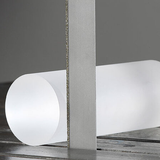

Bandsaw Blades

Industrial Bandsaw Blades for Metal & Wood Cutting

Industrial bandsaw blades are precision-engineered cutting tools used on bandsaw machines to slice through metal, wood, plastics, composites, and other materials. These blades are available in a variety of widths, tooth configurations, and materials to match the cutting requirements of different applications.

What Are Bandsaw Blades?

Bandsaw blades are long, continuous loops of toothed steel that rotate between wheels in a bandsaw machine. As the blade travels, the teeth bite into the workpiece and remove material. The design of the blade — including tooth pitch, set, and body thickness — determines how efficiently it cuts and how clean the cut surface will be.

Where Bandsaw Blades Are Used

Bandsaw blades are used in:

- Fabrication shops (metal and structural steel)

- Machine shops for cutting bar stock and pipe

- Woodworking and carpentry applications

- Maintenance and repair operations (MRO)

- Manufacturing environments requiring repeatable cuts

Types of Bandsaw Blades

Different blade types accommodate specific cutting needs:

- Standard carbon steel blades – For general purpose cutting in wood and soft metals

- High-speed steel (HSS) blades – Longer life and heat resistance for tough metals

- Tungsten carbide tipped (TCT) blades – Maximum durability for abrasive or exotic materials

- Bimetal blades – Flexible and durable for mixed metal cutting with long life

Key Cutting Parameters

The performance of a bandsaw blade depends on:

- Tooth pitch (TPI) — Fewer teeth per inch for thicker material, more for finer cuts

- Blade width — Wider blades resist deflection on straight cuts, narrower blades track curves

- Material and coating — Determines heat resistance, wear resistance, and blade life

Why the Right Bandsaw Blade Matters

Choosing the correct blade for the material and cut type ensures:

- Smoother, more accurate cuts

- Extended blade life

- Faster cutting speeds

- Less vibration and noise

- Reduced workload on the machine and operator

How to Select a Bandsaw Blade

- Match tooth pitch (TPI) to material thickness — fewer TPI for thicker material

- Choose blade width based on cut type (straight vs. curved)

- Select blade material for the material being cut (carbon, HSS, TCT, bimetal)

- Consider recommended speed and feed rates for the material and blade type

- Use coolant or lubricant where applicable to extend blade life

Common Cutting Mistakes and Solutions

- Using too fine a TPI on thick stock — leads to slow cutting and blade wear

- Using too coarse a TPI on thin material — poor finish and chattering

- Incorrect blade tension — causes bowing or tracking issues

- Not using lubrication on metal cutting — reduces blade life and creates heat buildup

Benefits of Quality Bandsaw Blades

- Higher productivity with faster and more consistent cutting

- Better finishes with less secondary work

- Longer blade life and reduced tooling costs

- Improved machine reliability and lower downtime

Frequently Asked Questions

What does TPI mean?

TPI stands for “teeth per inch.” Lower TPI (e.g., 3–6) is generally used for thick material, while higher TPI (10–14) is better for thin material and smoother surface finish.

How do I know what blade material to choose?

Blade material depends on the cutting application: carbon steel for lighter jobs, bimetal for general metal cutting, HSS for high heat/extended life, and TCT for abrasive or tough materials.

Why is blade width important?

Wider blades resist deflection and maintain straight cuts, while narrower blades allow tight radius cuts.

Related Categories

- Cutting Tools

- CNC Tooling & Accessories

- Band Saw Machines & Accessories

- Metalworking Abrasives

There are no products listed under this category.