Elevating Performance: Why Automatic Lubrication is Essential for Aerospace Applications

The aerospace industry demands the highest levels of precision and reliability. In the unforgiving environment of aircraft and engine components, proper lubrication isn't just routine maintenance—it's critical for safety, efficiency, and component lifespan. For new systems and retrofits, an automatic lubrication system from Bijur Delimon provides the optimized solution.

The Problem with Manual Lubrication in Aircraft

In complex aerospace machinery, achieving the "Optimal Lubrication Zone" is extremely difficult with manual methods. Manual lubrication often leads to a cycle of "feast or famine":

- Under-lubrication: This causes increased friction, excessive wear on vital components, and significantly reduces equipment life, increasing the risk of costly and unscheduled downtime.

- Over-lubrication: Excess lubricant can contaminate the coolant, diminish the performance of grinding processes, and even lead to collapsed seals and higher operating temperatures.

In an industry where precision is everything, this inconsistency is a major operational risk.

The Bijur Delimon Solution: Precision Automatic Lubrication

Bijur Delimon's engineered lubrication technology is designed to eliminate these issues by ensuring that only the proper amount of lubricant is dispensed at the correct frequency, making over-lubrication a problem of the past.

By delivering controlled amounts of lubricant while the equipment is running, an aerospace lubrication system maximizes uptime and extends the life of critical components, protecting your substantial equipment investment.

Featured Products for Reliable Aerospace Lubrication

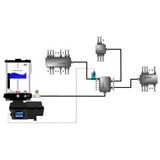

Bijur Delimon offers several key components for building a robust and reliable automatic lubrication system:

- M2500G Valve: A principal component of progressive lubricating systems, these Zinc-Nickel plated steel divider valve manifolds offer superior corrosion resistance and longevity. Their modular construction makes them easy to install, modify, and maintain without removing any tubing.

- FL Injector: These positive displacement grease dispensing valves are designed for high-performance applications. Featuring Viton O-rings as a standard, they are protected against high heat and synthetic lubricants—essential for aerospace environments. They are also interchangeable with major competitive brands.

- MultiPort II Lubricator: This electrically driven unit works with progressive divider valve systems to accurately control the amount of grease. With an integral controller, it monitors system performance and is specifically designed to endure harsh environments.

Achieve Operational Excellence with a Custom System

Whether you need lubrication equipment for a new design or a retrofit system, Bijur Delimon has the technical support and the right

Need a system designed for your specific aerospace application?

Recent Posts

-

Elevating Performance: Why Automatic Lubrication is Essential for Aerospace Applications

The aerospace industry demands the highest levels of precision and reliability. In the unforgiving e …Dec 10th 2025 -

Choosing the Right Band Saw Blade: Why Material, Application, and Engineering Matter More Than Ever

When it comes to metal cutting, productivity is directly tied to choosing the right band saw blade. …Nov 13th 2025 -

Centralized Lubrication vs Manual Greasing: When It’s Time to Upgrade

If your team is still chasing grease points with a gun and a clipboard, you’re not alone. Manual lub …Nov 13th 2025