Choosing the Right Band Saw Blade: Why Material, Application, and Engineering Matter More Than Ever

When it comes to metal cutting, productivity is directly tied to choosing the right band saw blade. The wrong blade increases heat, vibration, premature tooth wear, and material waste — while the right blade delivers cleaner cuts, higher feed rates, longer blade life, and dramatically lower cost per cut.

As shops take on new alloys, harder materials, and higher-volume production demands, engineering-driven blade selection becomes essential. That’s where brands like WIKUS stand out: not just because of blade quality, but because of the technical support behind each recommendation.

In this article, we break down why blade selection matters, how blade testing works, and how choosing the right blade can transform your sawing performance.

Why Blade Selection Matters

Every sawing application is different. Even two shops cutting the same grade of steel may require different blades based on:

- Feed and speed settings

- Saw type and horsepower

- Bundle vs. single-bar cutting

- Coolant quality and concentration

- Required surface finish

- Material hardness

- Operator experience

This is why high-performance blades are engineered with different tooth pitches, profiles, coatings, and backing materials—because the blade must match the job.

The Shift Toward Harder, More Demanding Materials

Manufacturers are increasingly machining difficult metals:

- Nickel-based superalloys

- Case-hardened steels

- Tool steels & quenched/tempered steels

- Stainless steel families 300–400

- Duplex & super duplex

- Aerospace-grade titanium

- Composite materials

Traditional bimetal blades struggle in these environments, especially when operators push for higher throughput. Shops now require:

- Higher heat resistance

- Superior wear protection

- Stable tooth geometry under load

- Lower vibration at aggressive feeds

This is where carbide-tipped and coated blades (Diamond, CBN) become essential.

The Role of Engineering: Why Testing Matters

WIKUS offers a structured process for evaluating your application through a Blade Performance Test. This is especially helpful when:

- Cutting new or exotic materials

- Increasing production speeds

- Experiencing premature blade failure

- Moving to automated or CNC sawing

- Seeking lower cost-per-cut

- Switching blade brands

The Blade Testing Process Typically Includes:

1. Reviewing material specifications

Size, grade, hardness, heat treatment, and shape (solid, tube, bundle, casting).

2. Evaluating the sawing machine

Horsepower, blade length, coolant quality, feed control, and blade tension system.

3. Selecting blade type & tooth pitch

Matching tooth geometry to feed pressure and chip load.

4. Validating speeds and feeds

Recommending optimized parameters to maximize life and performance.

5. Running the evaluation

Tracking longevity, cut quality, stability, and consistency.

6. Documenting cost-per-cut improvements

Blade life × cut time × operator efficiency.

This process allows the blade manufacturer to make a data-backed recommendation tailored to your equipment and production needs.

Understanding the Different Types of Advanced Coated Blades

Diamond-Coated Blades (DIAGRIT®)

Best for carbide, ceramics, composites, glass, graphite, and extremely hard materials.

Diamond delivers unmatched hardness and wear resistance.

CBN-Coated Blades (CUBOGRIT®)

Ideal for case-hardened steels, nitrided steels, tool steels, and hardened bearing steels.

CBN is the second-hardest material on earth and offers superior thermal stability.

Carbide-Tipped Blades

Perfect for high-nickel alloys, stainless steels, titanium, and abrasive metals.

They resist heat and provide longer life in demanding production cuts.

Each blade technology exists for a very specific cutting challenge — and using the wrong one can drastically limit performance.

Case Study: How the Right Blade Reduces Cost Per Cut

A customer cutting 4140 hardened shafting at high volumes may experience:

- Burning or discoloration

- Tooth chipping

- Increased vibration

- Slow cutting performance

Switching to a properly matched carbide-tipped blade (such as WIKUS TARANIS® or CT-flex® 3000) can lead to:

- 2–4× longer blade life

- 20–40% faster cut times

- Reduced kerf variation

- Cleaner, more accurate finishes

- Lower operator intervention

This real-world improvement is why testing is important — not every application fits a standard blade.

The Value of Partnering With a Technical Distributor

Cutting performance isn’t just about buying a blade — it’s about tuning the entire cutting system.

A technical distributor (like L. DeWitt McCarter) helps you with:

- Blade selection

- Feed + speed optimization

- Coolant recommendations

- Troubleshooting failure causes

- Application-based testing

- Inventory control and reorder planning

With support from WIKUS engineering, we ensure that you get the right blade, the first time.

When Should You Request a Blade Evaluation?

You should request a test if:

✔ You’re switching to a harder or more exotic material

✔ You want longer blade life

✔ You’re upgrading or replacing your saw

✔ You experience frequent blade breakage

✔ You’re trying to lower your cost per cut

✔ You want to compare WIKUS against your current brand

✔ You’re moving into automated or CNC sawing

Even small improvements create big savings in full-time production.

Conclusion: Better Blades = Better Production

Your band saw blade is one of the lowest-cost components on the production floor, yet it has one of the highest impacts on profitability.

The key is matching:

- The right blade,

- With the right material,

- Using the right parameters,

- Backed by engineering support.

This is where WIKUS blades — and the testing process — truly shine.

Recent Posts

-

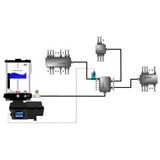

Elevating Performance: Why Automatic Lubrication is Essential for Aerospace Applications

The aerospace industry demands the highest levels of precision and reliability. In the unforgiving e …Dec 10th 2025 -

Choosing the Right Band Saw Blade: Why Material, Application, and Engineering Matter More Than Ever

When it comes to metal cutting, productivity is directly tied to choosing the right band saw blade. …Nov 13th 2025 -

Centralized Lubrication vs Manual Greasing: When It’s Time to Upgrade

If your team is still chasing grease points with a gun and a clipboard, you’re not alone. Manual lub …Nov 13th 2025