Centralized Lubrication vs Manual Greasing: When It’s Time to Upgrade

If your team is still chasing grease points with a gun and a clipboard, you’re not alone. Manual lubrication is where most plants start. But, it’s also where a lot of unplanned downtime, premature bearing failures, and safety issues begin.

At a certain point, “just grease it more often” stops working. That’s where centralized lubrication systems come in: one pump, one reservoir, and a network of metered lines that keep every critical point supplied with the right amount of lubricant—automatically.

In this article, we’ll walk through:

- Why manual greasing breaks down in real-world production

- What a centralized system actually does

- The key components (pump, meter units, monitoring)

- Simple triggers that tell you it’s time to step up

- How to start scoping a system for your equipment

We’ll keep the tone straightforward and technical, but we won’t forget the business case.

The Limits of Manual Greasing

Manual lubrication sounds simple: send someone out with a grease gun or oil can and hit all the points on a schedule.

In practice, it usually looks like this:

- Missed points

Some fittings are hard to reach, hidden behind guarding, or buried in the machine. Those are often the ones that fail first. - Over- and under-greasing

One mechanic gives a bearing two pumps. The next gives it ten. Too little lubricant leads to metal-on-metal contact; too much can blow seals and create excess heat. - Inconsistent intervals

Lubrication routes get delayed for production, night shift is short-staffed, someone calls in sick… and suddenly a “weekly” task is happening every 2–3 weeks. - Safety exposure

Technicians climb on, under, or into equipment to reach fittings. That’s fall risk, pinch points, and lockout/tagout complexity every single time. - No real traceability

When a bearing fails, it’s hard to answer: was it lubricated on time and in the right amount? Or did we just assume it was?

If you’re seeing repeat failures on the same assets, excessive grease usage, or technicians constantly fighting for access windows, you’re already paying for a more reliable solution—you’re just not getting the benefit yet.

What a Centralized Lubrication System Actually Does

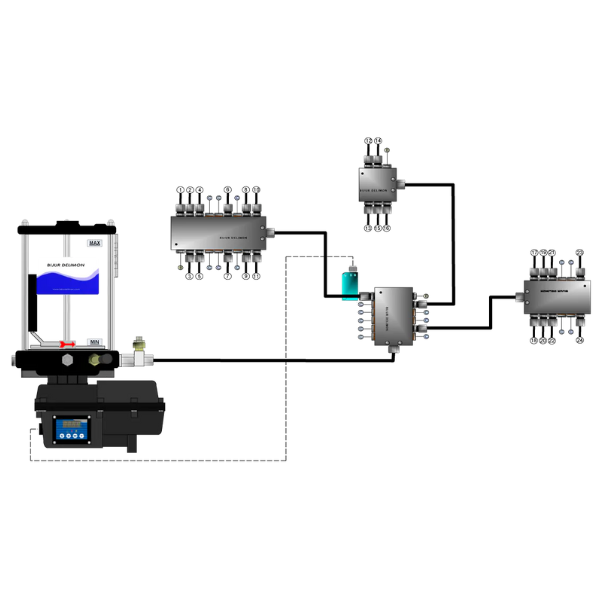

A centralized lubrication system automates the delivery of lubricant from a single reservoir and pump to multiple lubrication points throughout the machine.

At a high level, the system:

- Holds lubricant – usually oil or fluid grease in a reservoir.

- Pumps it under pressure on a timed or demand-based cycle.

- Meters flow to each lubrication point using calibrated components (meter units).

- Distributes lubricant through a network of tubing/lines.

- Monitors system health (pressure, flow, cycle completion, level) and alarms when something is wrong.

Instead of relying on a person to remember the right amount of grease at the right interval, you let the system do it the same way every time.

Key Components: From Pump to Lube Point

Let’s break down the main building blocks using a typical Bijur Delimon-style system as a model.

1. The Pump / Lubricator

This is the heart of the system—the unit that stores the lubricant and moves it through the circuit.

A pump/lubricator like the SureFire II is designed specifically for centralized lubrication:

- Electric motor drive (often 115–230 VAC)

- Reservoir in steel or plastic, sized for the application

- Integrated controls or external guidance from a controller

- Check valves and outlet ports sized for the type of system (SLR, PDI, etc.)

On each cycle, the pump delivers a known volume of lubricant into the main line. That volume is then split by the distribution network.

2. Meter Units (FJB / FSA, etc.)

This is where the system gets precise.

Meter units are small, calibrated devices that control how much lubricant goes to each lubrication point. Different models (for example, FJB or FSA types) deliver specific volumes per cycle.

Typical characteristics:

- Fixed output per lubrication cycle

- Available in multiple flow “sizes” (e.g., 1/0, 2/0, 3/0, 1, 2, 3)

- Threaded connections suited to manifolds or individual lines

By choosing the right meter unit for each point, you can:

- Give high-load bearings more lubricant

- Give lightly loaded or smaller bearings less

- Avoid both starvation and waste

3. Controllers & Monitoring

Even a well-designed system needs feedback. That’s where controllers and monitors come in:

- Cycle controllers (e.g., SMAC-type controllers)

- Set the lubrication interval (e.g., every 10 minutes, every 30 minutes, etc.)

- Control pump cycle duration or stroke count

- Interface with machine control (PLC) to lock lubrication to machine operation

- Lube point or pressure monitors

- Confirm that pressure builds and release occurs as expected

- Detect line breaks, blockages, or empty reservoir conditions

- Provide alarm outputs to maintenance or control systems

This monitoring layer turns the lubricator into a maintainable system rather than a “black box.”

When Is It Time to Move to Centralized Lubrication?

Not every machine needs central lube. But certain conditions are big red flags that you’re outgrowing manual greasing.

You should seriously consider centralizing lubrication when:

- You have 10+ lubrication points on a machine that are serviced regularly

- Access is difficult or unsafe, requiring ladders, platforms, or extensive guarding removal

- Production schedule is tight, and lubrication tasks are constantly getting pushed or skipped

- The same bearings or chains fail more than once in a 12–18 month period

- Your grease/oil consumption is high, but you’re still seeing wear issues

- You’re expanding internationally or across multiple sites, and want consistent maintenance standards

In short: if lubrication is a constant headache, you’re already paying in downtime, labor, and parts. A central system simply channels those costs into something predictable and controlled.

How to Start Scoping a System (Without Overcomplicating It)

You don’t have to engineer the entire solution yourself. But having the right basic information makes system design much faster.

Here’s what we typically ask for:

- Machine type & application

- What kind of equipment is it (press, indexer, conveyor, CNC, etc.)?

- Environment: dusty, hot, outdoors, washdown, etc.?

- Number and location of lubrication points

- Bearings, cams, chains, slides, etc.

- Rough idea of physical layout (sketches or photos help)

- Lubricant type

- Oil or fluid grease?

- Viscosity (ISO grade) if available

- Operating pattern

- Continuous, intermittent, batch?

- Typical run time per shift

With that information, a distributor or system designer can:

- Recommend a pump/lubricator with the right reservoir size and voltage

- Select appropriate meter units for each point

- Suggest monitoring and optional controls

- Provide a bill of materials (tubing, fittings, manifolds, etc.) and a basic layout

The Business Case: Reliability, Safety, and Labor

The technical side is important—but centralized lubrication also has a very clear business justification.

- Reduced downtime

Consistent lubrication extends bearing and component life and reduces unexpected failures. - Lower labor cost per machine

Technicians can service the central reservoir and visually inspect lines instead of crawling all over the equipment. - Improved safety

Less time climbing onto or into moving equipment means fewer opportunities for accidents. - Traceability

Lubrication cycles are recorded, alarms are logged, and maintenance has a clear record of when and how lubrication occurred.

For plants that run multiple shifts or have limited maintenance manpower, centralized lubrication is often one of the highest-ROI reliability upgrades they can make.

Ready to Explore a Centralized System?

Whether you’re running a single machine or a full production line, a properly sized centralized lubrication system can:

- Standardize how lubrication is done

- Protect critical bearings, cams, and slides

- Free up your maintenance team to focus on higher-value tasks

If you’d like help evaluating a system for your equipment, share:

- Machine type and photos or a simple sketch

- Number of lubrication points

- Lubricant type (oil or grease)

- Your location (U.S. or international)

We’ll help you spec a complete solution—pump, meter units, monitoring, and hardware—built around your application, not just a catalog page.

Request a Centralized Lubrication Quote

Recent Posts

-

Elevating Performance: Why Automatic Lubrication is Essential for Aerospace Applications

The aerospace industry demands the highest levels of precision and reliability. In the unforgiving e …Dec 10th 2025 -

Choosing the Right Band Saw Blade: Why Material, Application, and Engineering Matter More Than Ever

When it comes to metal cutting, productivity is directly tied to choosing the right band saw blade. …Nov 13th 2025 -

Centralized Lubrication vs Manual Greasing: When It’s Time to Upgrade

If your team is still chasing grease points with a gun and a clipboard, you’re not alone. Manual lub …Nov 13th 2025